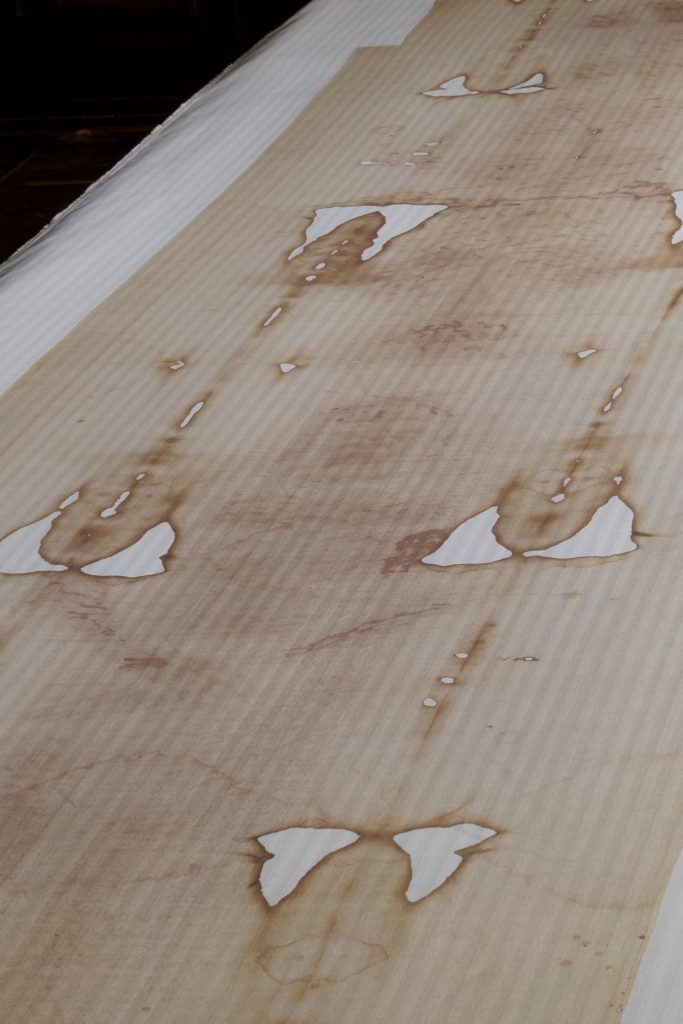

Full-scale, very high resolution to enhance its beauty

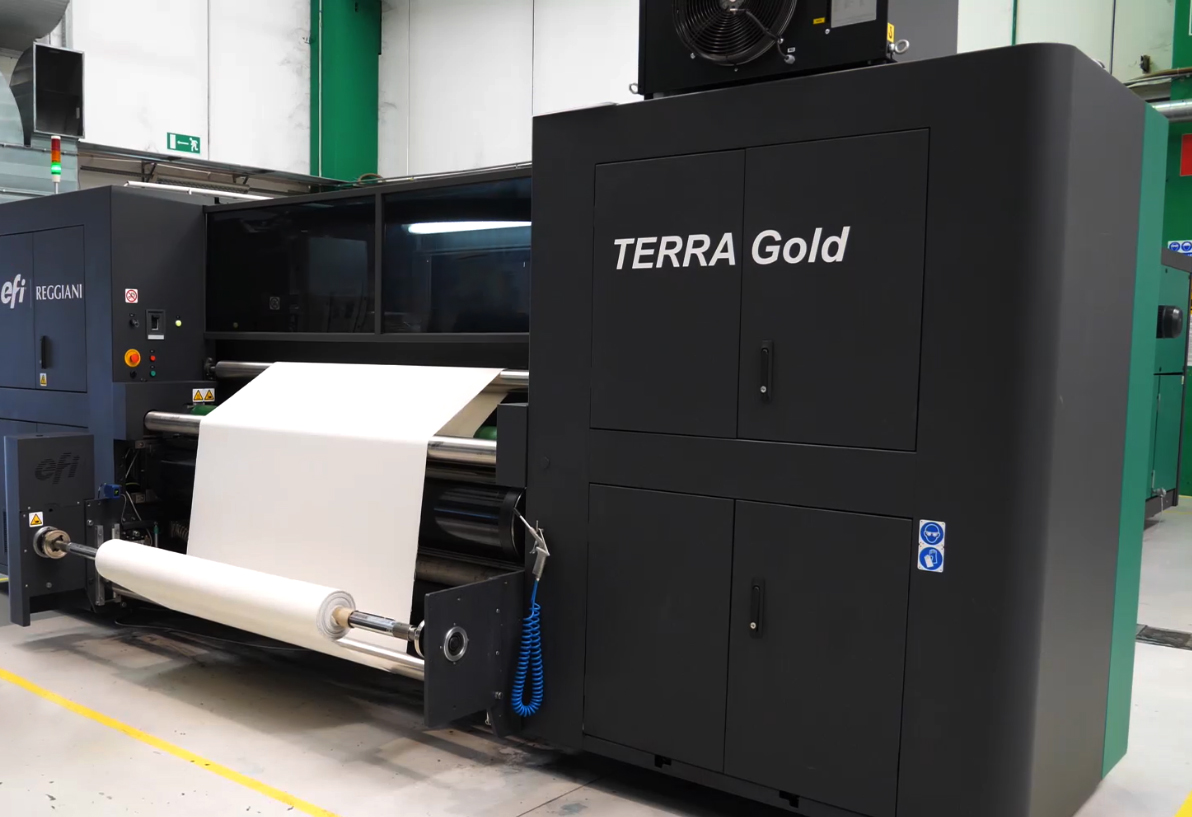

The Museum of the Shroud in Turin, in collaboration with the International Centre of Studies on the Shroud, has later ordered the printing phases to the EFI Reggiani of Grassobbio headquarters (Bergamo), one of the most famous worldwide company for the digital printing. The printing of frames in scale 1:1 (mt. 4,41 x 1,13 the original Shroud measurement) implies the use of a printing press with a high resolution in order to replicate all the details of the original yarn, to such an extent that the file needs the entire hard drive of a PC.